News

Major Production Success – 2022 Season

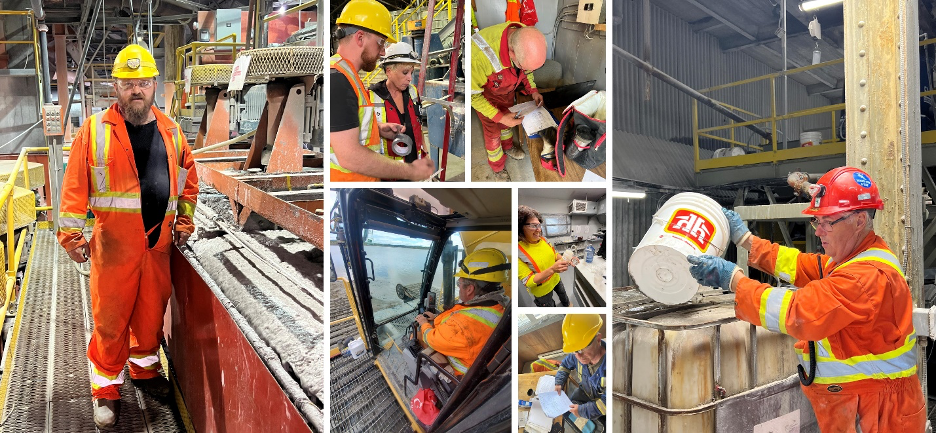

“Determination. Commitment. Science.” A few words offered by BarCan CEO Mike Rose describing the basis for 2022 barite production success.

“We will run out of product storage space very soon,” Rose added when describing major process improvements. “We are consistently producing high quality barite from old mine tailings, but this follows three years of intensive research and investment.”

In 2020, a new pumping system known as the “Eddy Pump” (see above) was successfully introduced. It mines the tailings at the bottom of the pond providing an optimal stream of raw material feed to the screens.

Then in 2021 intensive screening systems were introduced and ‘tweaked’ to solve long-standing process issues related to particle sizing. “But we would not have had the breakthrough success in 2022,” Rose said, “without an exhaustive tailings sampling program led by our consultants and supported by inhouse staff.”

New Product Development

During 2021 and 2022, BarCan has maintained an aggressive R&D program to create new barium-based derivatives for industrial uses in North American and European export markets. New barium products will expand BarCan’s global reach and improve BarCan’s market diversification. Support for this important new business unit development has been provided by NRC-IRAP, ACOA, and the Province.

BarCan is assessing its ability to make new barium-based products through reduction reaction processing of its primary product, API grade barite (drilling mud) or barium sulfate (BaSO4).

Laboratory trials have confirmed that BarCan’s BaSO4 successfully converts to barium sulfide (BaS) after high temperature roasting and dissolution. Barium sulfide (BaS) can be dissolved in water and precipitated into other barium products such barium carbonate (BaCO3), barium fluoride (BaF2), or synthetic barite.

BarCan is also completing laboratory trials to generate other marketable barium products such as barium chloride (BaCl2) and barium hydroxide (Ba(OH)2).

People and Technology

Since 2020, BarCan has also steadily invested in its people and supportive technologies. With support from the Province, ACOA and NRC-IRAP, we have introduced significant digital advancements. Accurate monitoring and control of mine processing functions are now, literally, at the fingertips of our staff.

Mike O’Brien, BarCan’s new General Manager, says “Every bit of success this year goes back to our staff. Our staff are top-notch problem-solvers and it is a real pleasure to be working with them.”

O’Brien notes, “Our ability to consistently place significant daily tonnage on the floor bodes well for future barium products coming out of Buchans. There are millions of tonnes to be processed in future years.”

Mike O’Brien, General Manager, (left) and Morgan Thorne, Process Control Coordinator.

Our People are the Best!

Barite Production Resumes June 2021

“Our latest multi-million dollar capital improvement program is almost complete— starting this month, we are on track to produce more high-quality barite,” says BarCan CEO Mike Rose.

New Processing Equipment

Derrick screens were installed last month to prevent oversized sands from infiltrating the milling process. The screening system integrates seamlessly with the dry feed system installed as part of 2020’s capital improvements. The powerful, newly-acquired amphibious excavator will provide a constant feed to the screens.

Mike Rose spoke about other capital improvements in the hopper for this year. “A major construction project by itself, we are installing a new thickener system to meet our production targets, which are significantly higher this year. To maximize production, we will reconfigure the regrind mill in the flotation circuit and retrofit our internal conveyor systems. It’s going to be a busy year!”

New Digital Technologies

BarCan embraced a digital automation strategy in 2020 and our employees are seeing the benefits.

Our EPCM consultant (Halyard) and processing advisors (Promet101) have designed a fiberoptic cable link between the mill and tailings pond, adding Human-Machine Interface (HMI) screens at key locations inside the mill, as well as communications wiring and micro controllers. As Gordana Slepcev, BarCan’s COO noted, “Digitization increases employee safety and delivers feedback in the key processes needed to produce high-quality barite.”

Research & Development

During 2021, BarCan is expanding its R&D program to create new barium-based derivatives for industrial uses in North American and European export markets. These new products will further expand BarCan’s global reach.

BarCan Barite Averages 4.3 s.g.

BarCan made a heavyweight achievement with production this year: BarCanBarite weighs in at an average of 4.3 specific gravity (s.g.), a low rate of impurities, and acceptable Pb levels.

CEO Mike Rose said of the 2020 results, “We’re very happy with the test results of a consistent average of 4.3, and we are continuing to optimize the product while maximizing volumes for 2021.”